For more information, Please call us

0086 15966662667

Give us a message

Message >>| Model | GTBZ-39 |

|

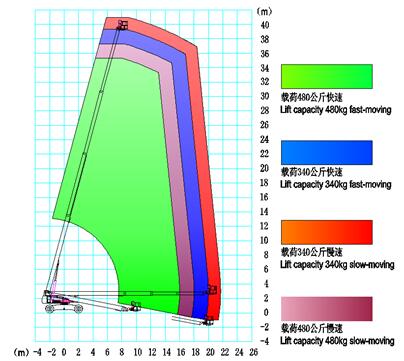

| Maximum Working Height | 41m | |

| Maximum Platform Height | 39.3m | |

| Maximum Horizontal Reach | 21.5m | |

| Platform capacity(restricted) | 480kg | |

| Platform capacity(non-restricted) | 260kg | |

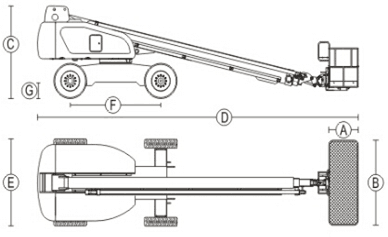

| Machine Length(stowed) Ⓓ | 13.9m | |

| Machine Width(axle retracted) Ⓔ | 2.49m | |

| Machine Width(axle extended) Ⓔ | 3.9m | |

| Machine Height(stowed) Ⓒ | 3.25m | |

| Wheel base Ⓕ | 3.96m | |

| Ground clearance-center Ⓖ | 430mm | |

| Platform Dimension(m) Ⓑ*Ⓐ | 2.44*0.91m | |

| Turning radius-inside,axle retracted | 4.1m | |

| Turning radius-outside,axle extended | 3.15m | |

| Turning radius-outside,axle retracted | 7.02m |

|

| Turning radius-outside,axle extended | 6.5m | |

| Drive speed(stowed) | 4.4km/h | |

| Drive speed(raised or extended) | 1.1km/h | |

| Gradeability-stowed | 40% | |

| Solid tire | 12.00-20 | |

| Swing speed | 0-1/3rpm | |

| Turntable swing | 360° Continuous | |

| Platform leveling | Automatical levelling | |

| Platform rotation | ±80° | |

| Fuel tank capacity | 151L | |

| Machine weight | 20600kg | |

| Voltage | 24v | |

| Drive & steering type | 4*4*4 | |

| Engine | Cummins B3.3-C80 | |

| Rated power | 60kw/2200rpm |

- 1 Suitable for shipyards, able to work in damp,corrosive,dusty, hot or cold environment.

- 2 Able to drive at all heights; drive speed decreases as platform height increases.

- 3 With double control modes(ground control mode and platform control mode); control mode is switchable. If platform control mode is on, ground control mode will be disabled.

- 4 Ground control mode can indicate temperature of engine lubricant, hydraulic oil pressure,water temperature and so on.

- 5 Engine has the function of hot restart under working state.

- 6 The arm is stable when stretching out,drawing back, rotating, and returning with damping mechanisms.

- 7 Stretching,retracting, rotate, returning and driving are proportional controlled with CVT function.

- 8 Reliable brake is equipped for driving and arm rotation, which can ensure that the equipment is under control during working state or on slopes. Manual rotary lock and brake release are equipped to enable the equipment can be towed.

- 9 If any single wheel suspends in the air, the other three wheels can still drive normally controlled by a distribution valve.

- 10 When the arm has an elevation angle against horizontal level or the retracting boom extend over 1.2m, there is a limit to the drive speed.

- 11Stretching out,drawing back,rotating,and returning of arms & driving can function simultaneously.

- 12 Working platform has automatic leveling function, and the working angle can not exceed 1.5°

- 13 Emergency stop button is installed on both platform control and ground control. In case of emergency situation, engine can be stopped immediately by operating the emergency stop button.

- 14 There is a foot pedal on the platform. Only when the foot pedal is stepped down, the equipment can be operated.

- 15 An Auxiliary power unit with 12v working voltage is equipped to enable the platform to lower to the ground in case of any malfunction of engine and pump.

- 16 Digital double circuit sensor can timely check length,angle and other parameters,to indicate the working state of arm. In case of malfunction of any circuit, the other circuit can still complete the task of checking parameters.

- 17 Working platform has a weighing function to check the loading capacity, and this weighing function is not related to the specific position in the platform. In case of overloading, there will be indication and alarm to ensure the safety.

- 18 Automatic gear shifting,alarm and cut-off: If rotation exceeds 80% of the max. allowed range, the speed of all the movement will decrease and there will be alarm of buzzing and flash. The closer the rotation gets to the mex. allowed range, the less the speed becomes, and the faster the alarm sound is. Once the rotation reaches the max. allowed range, all the dangerous movement will automatically stop.

- 19 There are 3 gears in the throttle control of the engine. When there is no operation for a long time, the engine will automatically switch to idling state, to save energy.

- 20 The move of arm will be limited when the equipment is on a ground unevenness is over 3°

- 21 There is working alarm during driving or arm rotation.

- 22 PLC and CAN are adopted to simplify the wiring and to facilitate maintenance. Air defence metal plugs are adopted with protection level up to IP65.

- 23 The air intake system adopts closed double filtration mechanism to meet the demand in dusty working environment, and the maintenance is very convenient.

- 24 Both ground control and platform control are protected with protection covers.

- 25 There are dust-proof and sand-proof devices at the boom end, piston rod of the cylinders and so on.

- 26 Hydraulic pump has functions of automatic pressure compensation and loading capacity sensing to ensure oil pump and engine will not get damaged owing to overloading.

- 27 The equipment has devices of overheat protection and automatic stop caused by low hydraulic pressure.

- 28 Safety valve is installed at the hydraulic circuit to avoid extra-high pressure in hydraulic system.

- 29 Hydraulic cylinders are equipped with balance valves and hydraulic interlocks to ensure that hydraulic cylinders do not operate automatically. And the connection of cylinders to balance valves and hydraulic interlocks is rigid.

- 30 Hydraulic parts and control parts are reliable with imported well-known brands.

- 31 Drag chain mechanism is sleeve patterned with patent. The sleeve is aluminum alloy section with process surface;To adapt to severe working conditions, the drag chain is high-strength engineering plastic which is resistant to maritime climate.

- 32 There are hoisting rings on both chassis and turret to facilitate hoisting.

-

33 labels and signs are clear with defined meaning.